With rising temperatures, soaring electricity costs, and increasing pressure to reduce carbon footprints, businesses and homeowners are actively seeking energy-efficient cooling alternatives to traditional air conditioning. One of the most sustainable and cost-effective solutions is evaporative cooling, especially suited to the Indian climate.

However, not all evaporative cooling systems work the same way. The two most common technologies are:

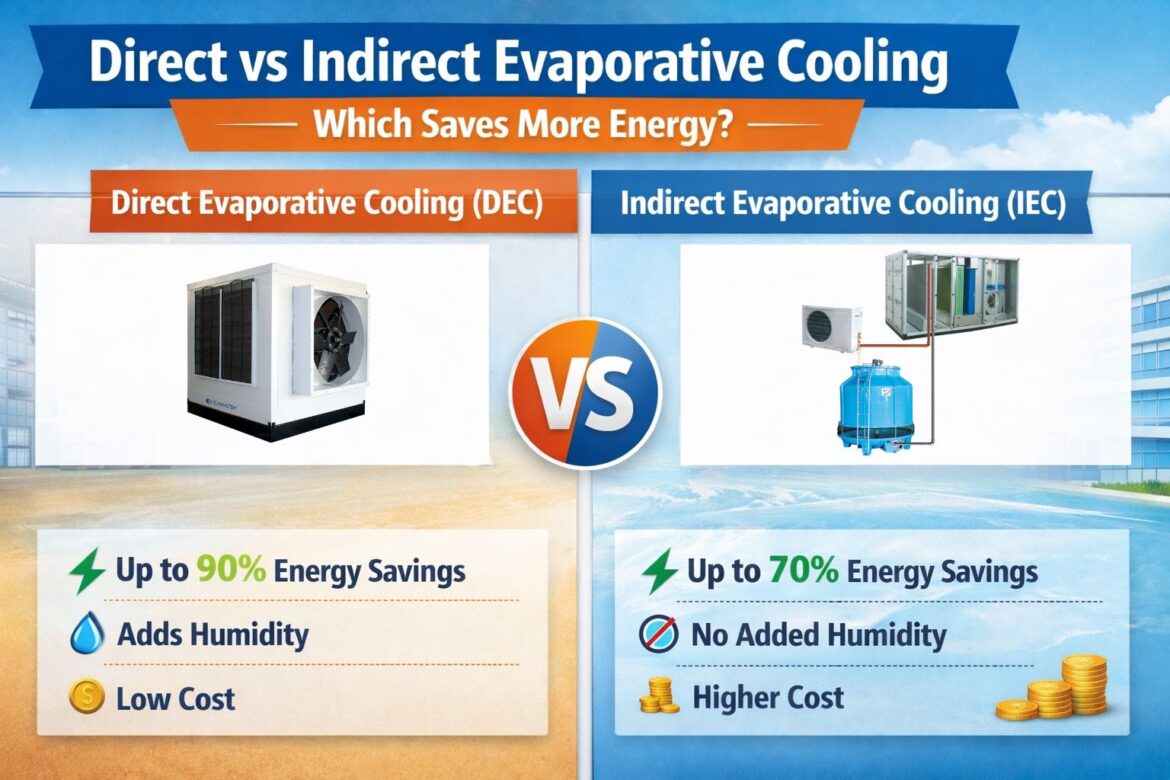

➧ Direct Evaporative Cooling (DEC)

➧ Indirect Evaporative Cooling (IEC)

Both use the natural process of water evaporation to cool air, but they differ in energy consumption, comfort level, humidity control, and application.

What Is Direct Evaporative Cooling (DEC)?

Direct Evaporative Cooling cools air by passing hot outdoor air through water-soaked cooling pads. As water evaporates, it absorbs heat from the air, reducing the temperature before the air enters the space.

How Direct Evaporative Cooling Works

● Hot outdoor air is drawn into the unit

● Air passes through wet cooling pads

● Evaporation reduces air temperature

● Cool, fresh air is supplied directly indoors

Key Benefits of Direct Evaporative Cooling

● Extremely low electricity consumption

● Supplies 100% fresh outdoor air

● Highly effective in hot and dry climates

● Simple design with low maintenance

● Lower capital cost than air conditioning systems

Energy Savings with DEC

Direct evaporative cooling can reduce electricity consumption by up to 80–90% compared to conventional air conditioning systems.

👉 Related reading: Is Evaporative Cooling Eco-Friendly?

What Is Indirect Evaporative Cooling (IEC)?

Indirect Evaporative Cooling cools air without adding moisture. It uses a heat exchanger, where evaporation occurs in a separate air stream that cools the supply air indirectly.

How Indirect Evaporative Cooling Works

● Outdoor air is cooled through evaporation in a secondary channel

● Heat is transferred via a heat exchanger

● Supply air temperature drops without absorbing moisture

● Cool, dry air is delivered indoors

Key Benefits of Indirect Evaporative Cooling

● No increase in indoor humidity

● Higher comfort in mixed or humid climates

● Ideal for temperature-sensitive environments

● Can be integrated with hybrid HVAC systems

Energy Savings with IEC

Indirect evaporative cooling systems typically reduce energy consumption by 60–70% compared to traditional air conditioning.

👉 Related reading:

How HVAC Systems Work in Commercial Buildings

| Parameter | Direct Evaporative Cooling | Indirect Evaporative Cooling |

|---|---|---|

| Energy savings | ⭐⭐⭐⭐⭐ (Highest) | ⭐⭐⭐⭐ |

| Humidity control | Adds humidity | No added humidity |

| Initial investment | Lower | Higher |

| Climate suitability | Hot & dry regions | Mixed & humid climates |

| Fresh air | 100% fresh air | 100% fresh air |

| Comfort level | Moderate | High |

Which Evaporative Cooling System Saves More Energy?

If maximum energy savings is the only criterion, Direct Evaporative Cooling is the clear winner. Its minimal power consumption and high airflow make it ideal for large, open spaces.

However, in applications where humidity control and thermal comfort are equally important, Indirect Evaporative Cooling provides a better balance between efficiency and comfort.

When Should You Choose Direct Evaporative Cooling?

Choose DEC if you need:

● Maximum electricity savings

● High fresh-air ventilation

● Cooling for open or semi-open areas

● Industrial or commercial cooling for large spaces

● Lower upfront cost

Best suited for: Warehouses, factories, workshops, farms, logistics centers, commercial areas, villas, and rooftops

👉 Learn more: Best HVAC Solutions for Warehouses & Factories & Evaporative Cooling Systems

When Should You Choose Indirect Evaporative Cooling?

Choose IEC if you need:

● Cooling without increasing humidity

● Higher comfort for enclosed spaces

● Energy-efficient alternative to air conditioning

● Temperature-controlled environments

Best suited for: Offices, IT parks, malls, data centers, hospitals, laboratories, clean rooms

👉 Useful links: Clean Room HVAC Solutions

Hybrid Cooling Systems: The Most Energy-Efficient Approach

Modern HVAC systems increasingly combine Indirect + Direct Evaporative Cooling or Evaporative Cooling + Air Conditioning.

Why Hybrid Cooling Works

➠ Reduces AC load by 40–60%

➠ Improves comfort and humidity control

➠ Enhances overall system efficiency

➠ Ideal for large commercial and industrial facilities

Why Choose Degree Day Pvt. Ltd.?

With 26 years of HVAC expertise, Degree Day Pvt. Ltd. designs and delivers custom evaporative and hybrid cooling solutions tailored to Indian climate conditions.

We offer:

➤ End-to-end HVAC EPC services

➤ Energy-efficient evaporative cooling systems

➤ HVAC design, installation & maintenance

➤ Proven experience across industrial & commercial projects

➤ Air Purifiers and Designer Bladeless Fans

FAQs Related to Direct vs Indirect Evaporative Cooling

Direct Evaporative Cooling saves the most energy, offering up to 90% power savings compared to air conditioning.

Indirect evaporative cooling and hybrid systems work better in humid or mixed climates.

Yes, direct evaporative cooling is ideal for large industrial spaces with high ventilation requirements.

In many applications, yes. In others, a hybrid system delivers the best performance.

Absolutely. Degree Day offers tailor-made HVAC designs based on climate, space, and energy goals.

✔ Direct Evaporative Cooling → Maximum energy savings

✔ Indirect Evaporative Cooling → Better comfort & humidity control

✔ Hybrid Systems → Best overall efficiency

Need expert guidance? Send an enquiry to Degree Day