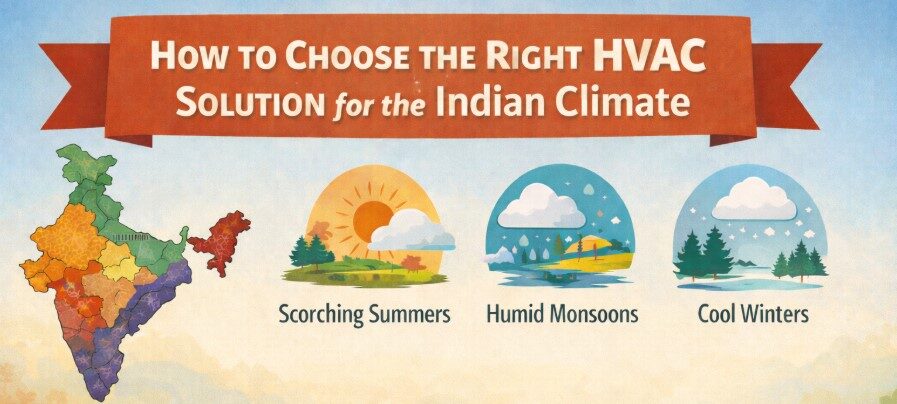

Choosing the right HVAC solution depends on several factors – location, building size, climate zone, usage patterns, budget, and long-term energy goals. In this blog, we break down the most common HVAC systems used in India, their performance in tropical conditions, energy costs, and maintenance needs, helping you make a smarter, climate-appropriate decision.

Understanding India’s Climate Challenges for HVAC Design

India has multiple climate zones: hot-dry, hot-humid, composite, coastal, and temperate, and each one affects HVAC performance differently. Seasonal extremes are common: scorching summers, humid monsoons, and mild to cold winters in some regions.

In tropical climates, HVAC systems must handle:

– Sensible heat (reducing temperature)

– Latent heat (removing moisture)

This dual demand makes HVAC design more complex. In fact, cooling systems in tropical regions can consume up to 56% of a building’s total energy, compared to 30–40% in temperate climates.

Seasonal variation also plays a big role:

– May–June: Cooling demand peaks at nearly 90–95% of system capacity.

– July–August (Monsoon): Humidity control becomes more important than temperature reduction. Overcooling during this period can actually worsen indoor humidity if not managed correctly.

This is why climate-responsive HVAC design is critical.

Common Cooling Systems Used in India (and How They Perform)

1. Window Air Conditioners

Best suited for small rooms and low-budget setups, window ACs are simple but inefficient in humid conditions. They struggle during monsoons and offer limited humidity control.

2. Split ACs (Non-Inverter & Inverter)

Non-inverter models consume more power and perform adequately, but inverter split ACs are far better suited for Indian climates. Their variable-speed compressors adjust cooling based on load, offering:

– Better humidity control

– 20–30% energy savings

– Longer compressor life

They are ideal for long-term residential and small commercial use.

3. Central Evaporative Cooling

Evaporative cooling is a smart, energy-efficient solution, especially for hot and dry climates. It works by naturally cooling the air, making spaces feel comfortable without the heavy power consumption of traditional air conditioning. Since the system adds moisture to the air, it’s best suited for dry weather and is usually paired with a backup option during the monsoon months.

One of its biggest advantages is efficiency; it uses up to 80% less electricity than conventional AC systems. For best performance, it is recommended for areas of 500 sq. ft. or more, making it ideal for spacious homes, offices, and commercial environments.

4. VRF / VRV Systems

These multi-zone systems offer excellent energy efficiency, precise temperature control, and superior humidity management. They are widely used in offices, hospitals, hotels, and large commercial buildings where occupancy varies throughout the day.

5. Solar-Powered Air Conditioning

Solar-integrated ACs significantly reduce grid electricity usage and operational costs. While the initial investment is high, they deliver excellent long-term returns in regions with high solar exposure.

Choosing the Right System by Space Type and Climate

Residential Use

● Single rooms: Inverter split ACs or window ACs

● Apartments: Inverter split ACs or hybrid evaporative + split systems

● Villas: VRF systems or hybrid solutions for mixed-use zones

Commercial & Institutional Buildings

● IT Parks & Offices: Central evaporative cooling with split AC backup

● Hotels & Hospitals: VRF systems with heat recovery

● Factories & Data Centers: Water-cooled chilled water systems

Each application requires a customized approach based on usage, occupancy, and load patterns.

Maintenance Needs in Tropical and Monsoon Conditions

Tropical climates demand more frequent and careful HVAC maintenance.

Monsoon-Specific Care (July–September)

● Clean filters every 2 weeks

● Ensure drain lines are clear to prevent water buildup

● Protect outdoor units from moisture and corrosion

● Install surge protection during thunderstorms

Annual Preventive Maintenance

● Servicing before peak summer and before monsoon

● Refrigerant leak checks

● Coil cleaning and airflow balancing

● Thermostat calibration

Regular maintenance (₹1,000–1,500 annually) can extend system life by 20–30% and prevent costly breakdowns.

Cost vs Efficiency: When Does It Make Sense to Upgrade?

1. Window Air Conditioners – Cost vs Efficiency

Window ACs are often the go-to choice when budget is the main concern. They’re affordable, easy to install, and work well for smaller rooms or occasional use. That said, they aren’t the most energy-efficient option. Over time, electricity bills can add up—especially if the unit runs for long hours every day. So while a window AC makes sense for short-term or limited use, it may not be the best pick if you’re looking for long-term savings.

2. Split ACs (Non-Inverter & Inverter) – Cost vs Efficiency

Non-inverter split ACs come with a lower price tag, but their frequent start-stop operation leads to higher power consumption. Inverter split ACs, on the other hand, cost more initially but are far easier on your electricity bills.

3. Central Evaporative Cooling – Cost vs Efficiency

Central evaporative cooling strikes an excellent balance between upfront cost and long-term efficiency. These systems are remarkably economical to run, consuming up to 80–93% less electricity than conventional air conditioning, especially in hot and dry climates. They are best suited for larger spaces, typically 500 sq. ft. and above, where energy consumption can otherwise become a major expense.

To put things into perspective, consider a 1000 sq. ft. area cooled using a 10,000 CFM system. A traditional AC would consume around 8 kWh, whereas Greencon’s E-Series evaporative cooler uses just about 1.1 kWh for the same space. That’s a massive reduction in power usage without compromising comfort.

While a backup system may be required during monsoon months due to higher humidity, the overall savings, both financial and environmental, make central evaporative cooling a truly cost-effective and sustainable choice for large spaces.

4. VRF / VRV Systems – Cost vs Efficiency

VRF and VRV systems do require a higher upfront investment, but they truly deliver when it comes to efficiency and control. By adjusting cooling output based on real-time demand, they avoid unnecessary power consumption. This makes them ideal for commercial buildings, hotels, and large offices where occupancy keeps changing. Over time, lower energy bills, minimal maintenance, and a long service life help these systems justify their initial cost.

5. Solar-Powered Air Conditioning – Cost vs Efficiency

Solar ACs sit at the premium end in terms of upfront cost, but their long-term payoff can be impressive. For those planning to stay in the same property for 15 years or more, solar cooling starts to make strong financial sense. With government subsidies and net metering, electricity costs can drop dramatically, sometimes nearly to zero. In the long run, solar ACs not only recover their cost but also offer protection against rising power tariffs.

Key Recommendations for Indian Homes & Businesses

1. Commercial & Institutional Buildings, IT Parks & Offices: Central Air Conditioning or Central evaporative cooling as backup

2. Hotels & Hospitals: VRF systems with heat recovery or Chilled Water System

3. Factories & Data Centers: Water-cooled chilled water system/VRF

How Degree Day Helps You Choose the Right HVAC Solution

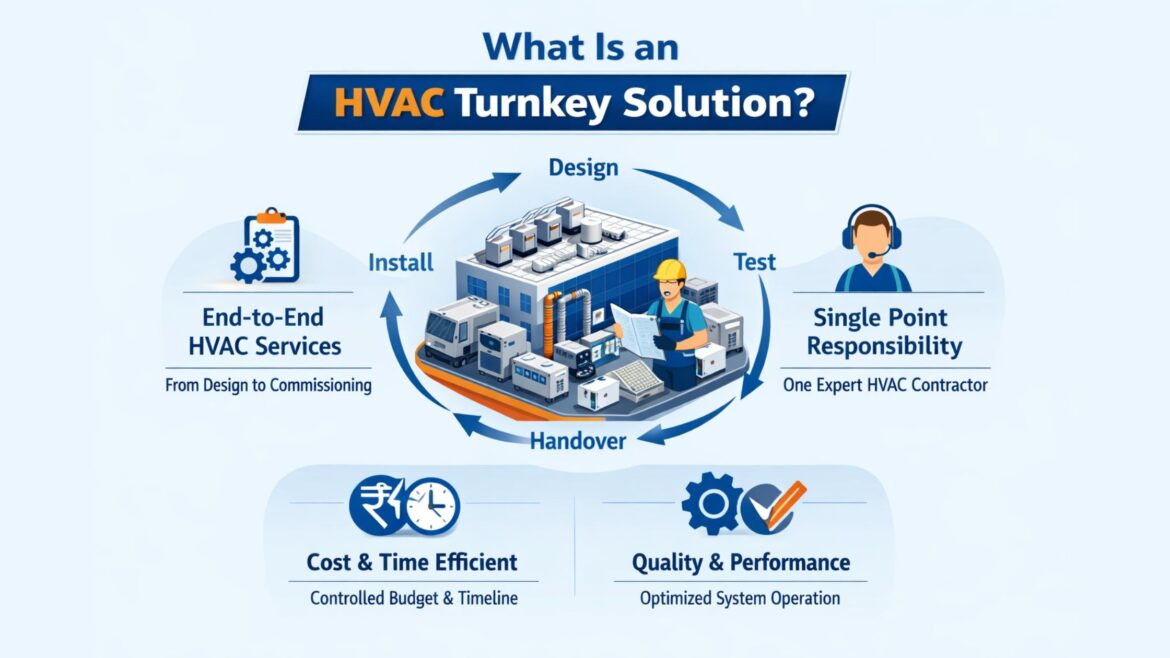

Selecting the right HVAC system is not just about equipment; it’s about design, execution, and long-term performance. This is where Degree Day Pvt. Ltd. plays a key role.

With over 26 years of experience, Degree Day specializes in:

● Climate-responsive HVAC design

● Energy-efficient cooling solutions

● Evaporative cooling systems

● Pre-fabricated ducting and air distribution

● Turnkey HVAC project execution

By combining technical expertise with real-world Indian climate understanding, Degree Day helps residential, commercial, and industrial clients achieve lower energy costs, better comfort, and long-term reliability.

There is no one-size-fits-all HVAC solution for India’s tropical climate. The best choice balances initial investment, operating costs, humidity control, and maintenance.

Ultimately, correct system sizing, professional installation, and regular maintenance matter just as much as the technology itself. A well-designed HVAC system is an investment that pays back every year through comfort, efficiency, and durability.

Frequently Asked Questions

1: What is the best HVAC system for Indian climate conditions? The best HVAC system for the Indian climate depends on the region and application. In hot-dry regions, central evaporative cooling is highly energy-efficient. In hot-humid and coastal areas, inverter split ACs or VRF systems perform better due to superior humidity control. For large commercial buildings, VRF or chilled water systems offer optimal efficiency, scalability, and long-term savings.

2: Why is humidity control important in HVAC systems for India? India’s tropical climate demands management of both sensible heat (temperature) and latent heat (humidity). During monsoon months, excessive cooling without proper dehumidification can increase indoor discomfort, cause condensation, and promote mold growth. HVAC systems with variable capacity control, proper ventilation, and moisture management ensure healthier and more comfortable indoor environments.

3: Is evaporative cooling suitable for all Indian climates? Evaporative cooling is best suited for hot and dry climates, where it delivers up to 80–93% energy savings compared to conventional air conditioning. However, in high-humidity or monsoon conditions, its effectiveness reduces. For year-round comfort, evaporative systems are often combined with backup split ACs or hybrid HVAC solutions.

4: How do inverter ACs save energy in Indian homes and offices? Inverter ACs use variable-speed compressors that adjust cooling output based on real-time demand. This reduces frequent start-stop cycles, resulting in 20–30% lower electricity consumption, improved humidity control, quieter operation, and longer equipment life. They are ideal for Indian households and offices with long daily usage hours.

5: How often should HVAC systems be serviced in tropical and monsoon climates? In tropical regions like India, HVAC systems require preventive maintenance at least twice a year, before peak summer and before monsoon. During monsoon months, filters should be cleaned every 2 weeks, drain lines checked regularly, and outdoor units protected from moisture. Regular servicing can extend system life by 20–30% and significantly reduce breakdown costs.