As buildings grow larger and more complex, HVAC systems have become one of the most critical and challenging parts of construction. Managing multiple vendors, coordinating timelines, controlling costs, and ensuring system performance often leads to delays and inefficiencies.

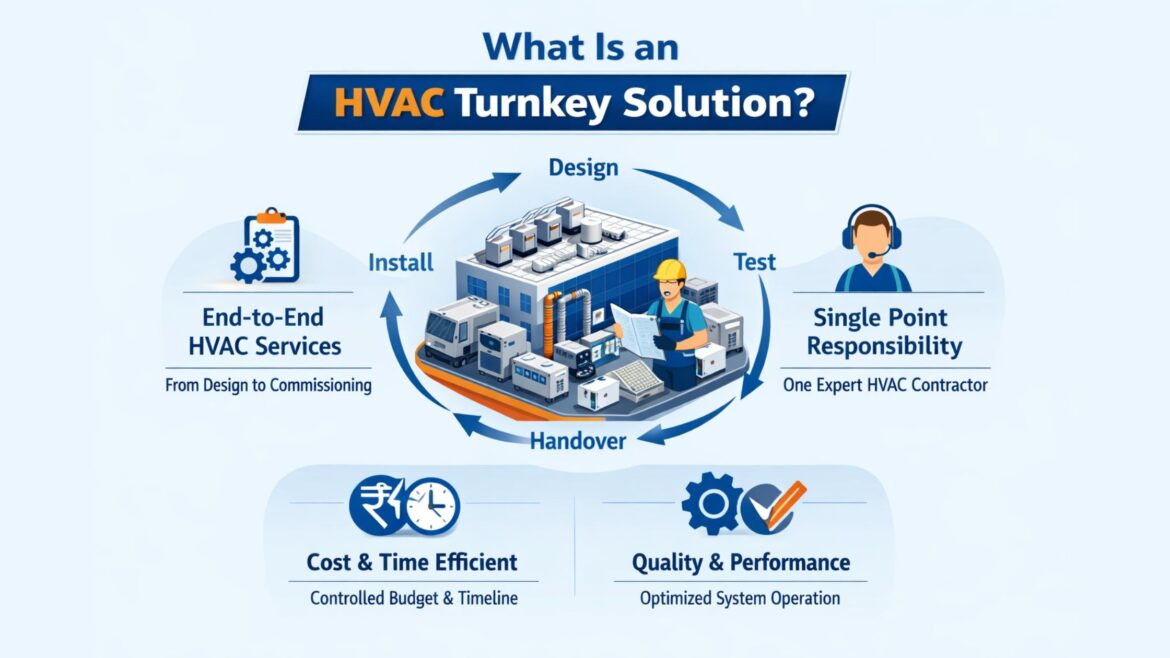

An HVAC turnkey solution is a comprehensive, end-to-end service where a single HVAC provider takes full responsibility for the entire project lifecycle. Once the project is handed over, the system is fully designed, installed, tested, and ready for operation, hence the term “turnkey.”

Instead of dealing with multiple contractors for design, equipment supply, installation, and commissioning, the client works with one accountable partner.

1. What Does an HVAC Turnkey Solution Include?

A complete HVAC turnkey solution typically covers:

1. System Design & Engineering

➤ Heat load calculations

➤ HVAC system selection based on building use and climate

➤ Energy-efficient and code-compliant design

2. Equipment Supply

➤ Chillers, AHUs, FCUs, evaporative cooling units, air purifiers

➤ Ducting, piping, insulation, controls, and accessories

3. Installation & Execution

➤ Ducting and piping installation

➤ Electrical and control wiring

➤ Mechanical equipment installation

4. Testing & Commissioning

➤ Air balancing and system testing

➤ Performance verification

➤ Safety and quality checks

5. Handover & Support

➤ As-built drawings

➤ Operation and maintenance guidance

➤ Warranty and after-sales support

2. How is an HVAC Turnkey Project Different from Traditional HVAC Contracting?

| Traditional HVAC Approach | HVAC Turnkey Solution |

|---|---|

| Multiple vendors | Single point of responsibility |

| Coordination challenges | Seamless execution |

| Higher risk of delays | Controlled timelines |

| Cost variations | Better cost predictability |

| Limited accountability | Full project ownership |

With a turnkey model, responsibility does not shift between parties; one partner is accountable for performance, quality, and delivery.

3. Key Benefits of an HVAC Turnkey Solution

1. Single-Point Accountability – Clients communicate with one expert partner, reducing confusion and misalignment.

2. Faster Project Execution – Integrated planning and execution eliminate delays caused by multiple contractors.

3. Cost Control & Transparency – Accurate budgeting and reduced chances of hidden or duplicate costs.

4. Optimized System Performance – Design, equipment selection, and installation are aligned for maximum efficiency.

5. Energy Efficiency & Compliance – Turnkey solutions ensure adherence to standards such as ASHRAE, ISHRAE, and local building norms.

4. Who Should Choose an HVAC Turnkey Solution?

HVAC turnkey solutions are ideal for:

➤ Commercial buildings & offices

➤ Industrial plants & factories

➤ Hospitals & healthcare facilities

➤ Warehouses & logistics centers

➤ Malls, multiplexes, and large retail spaces

➤ Educational institutions

Any project where performance, timelines, and lifecycle cost matter benefits from a turnkey approach.

5. HVAC Turnkey Execution: Experience from Degree Day Projects

At Degree Day Pvt. Ltd., HVAC turnkey solutions are executed with a strong focus on performance, energy efficiency, and long-term reliability. Our experience across commercial, industrial, and large-volume air cooling projects has demonstrated the practical advantages of turnkey execution.

★ Commercial Building HVAC Projects

In multiple commercial building projects, Degree Day delivered complete HVAC turnkey solutions from system design and equipment selection to installation and commissioning. By integrating efficient air cooling and ventilation strategies, these projects achieved reduced energy consumption and consistent indoor comfort, even during peak summer conditions.

Recent Turnkey Projects of Degree Day Pvt. Ltd. in Commercial Buildings

1. Spectrum Mall: Shopping mall in Indore, Madhya Pradesh

2. NRK Tower: Commercial buildings by NRK Group in Indore

3. Yash Technology: Global IT services and outsourcing company in Indore

4. Bombay International School in Indore

★ Industrial & Manufacturing Facilities

For factories and industrial units, Degree Day has executed turnkey HVAC solutions designed for high heat loads, long operating hours, and dust-prone environments. Centralized evaporative cooling systems and engineered ducting layouts helped improve working conditions while keeping operating costs under control.

Recent Turnkey Projects of Degree Day Pvt. Ltd. in Industrial & Manufacturing Facilities

1. AJFPL Neemrana: Leading automotive friction material manufacturer in Neemrana, Rajasthan

2. Gufic Biosciences Ltd: Manufacture of pharmaceuticals, medicinal chemicals, and botanical products

3. Techture: A consulting firm delivering solutions for the Architecture, Engineering, and Construction (AEC) industry.

4. Tirupati Group: Tirupati is a leading Indian contract manufacturer offering end-to-end healthcare and nutraceutical solutions.

★ Large-Scale Air Cooling & Ventilation Projects

Degree Day’s turnkey expertise also extends to warehouses and large enclosed spaces, where conventional air conditioning is often impractical. Climate-appropriate turnkey air cooling solutions were implemented to ensure uniform airflow, lower power consumption, and minimal maintenance requirements.

Recent Turnkey Projects of Degree Day Pvt. Ltd. in Large-Scale Air Cooling & Ventilation Projects

1. Millennium Baby Care: Baby Diapers, Adult Diapers, and Sanitary Napkins Manufacturer in Pithampur, Madhya Pradesh.

2. Dcnpl Hills Vistaa: Premium Township in Bhawrasla, Indore

3. Kohinoor Elastic: Fabric product manufacturer in Indore, Madhya Pradesh

4. Remedium Lifesciences: Tablet and capsule pharmaceutical manufacturing unit at Mandideep, Madhya Pradesh.

Across these projects, a single-point responsibility model enabled:

➤ Faster execution timelines

➤ Better coordination across trades

➤ Consistent quality control

➤ Optimized system performance

6. HVAC Turnkey Solutions in the Indian Climate

India’s climate presents unique challenges, including high temperatures, humidity, dust, and long operating hours. An HVAC turnkey solution helps address these by:

➤ Designing systems specific to hot-dry, composite, or humid zones

➤ Selecting energy-efficient solutions like evaporative cooling, where applicable

➤ Ensuring durability and lower maintenance in harsh conditions

A climate-responsive turnkey design results in lower operating costs and longer system life.

7. Common Challenges Solved by HVAC Turnkey Solutions

➤ Poor coordination between contractors

➤ Oversized or undersized HVAC systems

➤ Unexpected cost escalations

➤ Inconsistent installation quality

➤ Delays in commissioning

Turnkey execution eliminates these risks by aligning design, execution, and accountability.

8. Why HVAC Turnkey Solutions Are the Future

With rising energy costs, stricter building norms, and increasing demand for indoor comfort, HVAC systems can no longer be treated as standalone components. A turnkey approach ensures integration, efficiency, and reliability, making it the preferred choice for modern infrastructure projects.

9. Choosing the Right HVAC Turnkey Partner

When selecting an HVAC turnkey provider, look for:

➤ Proven project experience

➤ Strong in-house design and engineering team

➤ Quality-focused execution standards

➤ Energy-efficient solution expertise

➤ Reliable post-installation support

A capable turnkey partner adds value not just during construction, but throughout the system’s lifecycle.

An HVAC turnkey solution simplifies complexity, reduces risk, and delivers reliable performance, making it a smart investment for any large or performance-driven building project.

By choosing the right turnkey partner, building owners gain peace of mind, predictable costs, and HVAC systems designed to perform efficiently for years to come.

Looking for a reliable HVAC turnkey partner for your next project? Degree Day delivers climate-responsive, energy-efficient HVAC turnkey solutions tailored to Indian buildings.

Frequently Asked Questions

An HVAC turnkey solution is an end-to-end HVAC service where a single contractor handles system design, equipment supply, installation, testing, commissioning, and handover, ensuring full accountability and seamless execution.

An HVAC turnkey project typically includes HVAC design and engineering, equipment procurement, ducting and piping installation, electrical and control integration, testing, commissioning, and post-installation support.

Unlike traditional HVAC contracting, where multiple vendors are involved, an HVAC turnkey solution offers single-point responsibility, better coordination, controlled costs, faster execution, and improved system performance.

The main benefits include reduced project risk, predictable timelines, cost transparency, optimized HVAC system performance, energy efficiency, and compliance with Indian and international HVAC standards.

Yes, HVAC turnkey solutions can include evaporative air cooling systems, especially for factories, warehouses, and large spaces where energy-efficient cooling is required for Indian climate conditions.

Before hiring an HVAC turnkey contractor, verify their project experience, in-house design capabilities, quality standards, energy efficiency expertise, compliance with ISHRAE/ASHRAE guidelines, and after-sales support.