When designing an HVAC system or buying a new HVAC system, one of the most critical decisions is choosing the right duct material. The two most common options are Stainless Steel (SS) and Mild Steel (MS) ducts. Each comes with its own set of advantages, costs, and ideal applications. Understanding their differences can help you make a more informed choice for efficiency, durability, and long-term performance.

1. Corrosion Resistance

Stainless Steel is naturally resistant to rust and corrosion, making it ideal for humid, coastal, or industrial environments. Mild Steel, on the other hand, is prone to rust and typically requires galvanization or painting for protection.

If your system operates in a corrosive environment, SS is the safer choice.

2. Strength and Durability

SS ducts are extremely strong and maintain structural integrity over long periods, even under heavy stress. MS ducts are durable too but may warp or weaken over time in harsh conditions.

3. Weight and Handling

Mild Steel is lighter and easier to handle during transportation and installation. Stainless Steel is slightly heavier, which can make installation more labor-intensive but adds to long-term durability.

4. Cost Considerations

SS ducts come with a higher upfront cost due to the material itself and fabrication requirements. MS ducts are more budget-friendly, making them suitable for cost-conscious projects in non-corrosive environments.

5. Hygiene and Maintenance

Stainless Steel is easy to clean and maintain, making it ideal for hospitals, kitchens, and food-processing areas where hygiene is critical. Mild Steel requires more upkeep to prevent rust and contamination.

6. Ideal Applications

➤ Stainless Steel Ducts: Hospitals, laboratories, coastal areas, industrial environments with corrosive air.

➤ Mild Steel Ducts: Commercial buildings, offices, residential complexes, and non-corrosive areas.

With Degree Day, India’s largest manufacturer of Stainless Steel and Mild Steel ducts, you get high-quality, fully customized HVAC duct solutions designed to last decades. Our ducts are engineered to deliver optimal airflow, superior hygiene, and maximum energy efficiency, making them ideal for a wide range of applications from residential and commercial buildings to hospitals, labs, and industrial facilities.

We combine state-of-the-art manufacturing technology with rigorous quality checks, ensuring every duct meets international standards. Our Stainless Steel ducts are perfect for corrosive, humid, or hygienically sensitive environments, while our Mild Steel ducts provide cost-effective, reliable solutions for non-corrosive spaces.

Read Our Duct Related Blogs

For more insights on HVAC ducts, materials, and systems, check out these informative blogs from Degree Day Pvt. Ltd.:

➤ Galvanized Iron (GI) vs Stainless Steel Ducts: Which Performs Better?

➤ Which HVAC System Suits Your Industry? A Complete Guide for Every Sector

➤ Best HVAC Solutions for Warehouses & Factories

➤ Prefabricated vs Handmade Ducts: Which Is Right?

➤ How to Choose the Right Duct Material

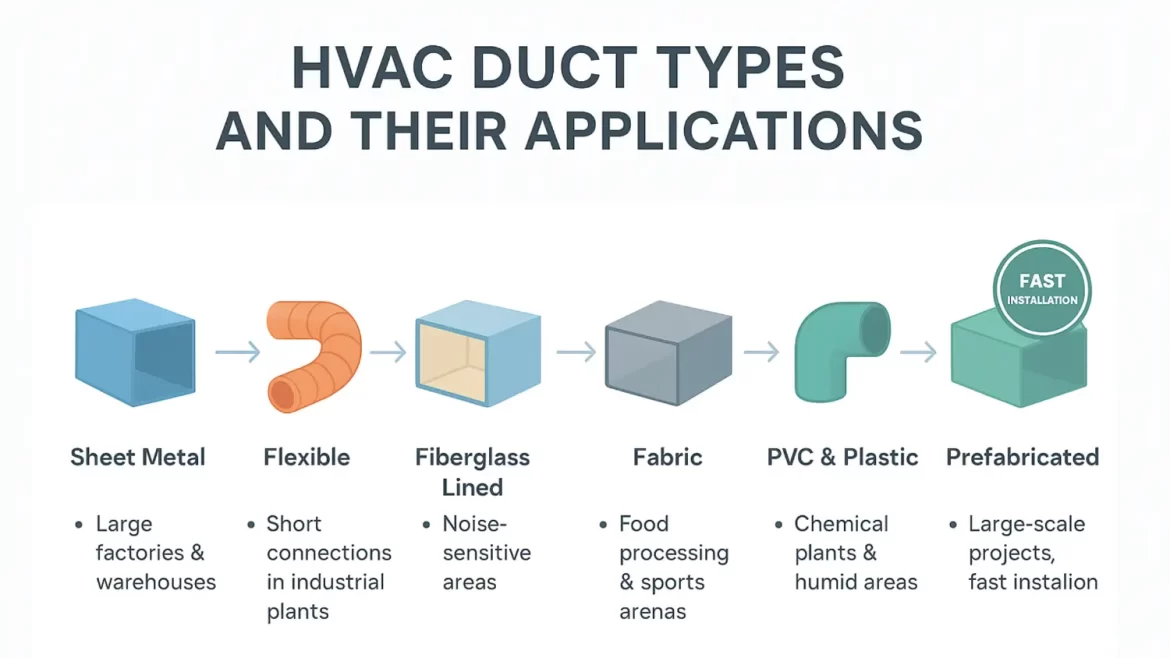

➤ Types of HVAC Ducts and Their Applications

➤ What Is CFM in HVAC and Why Does It Matter for Your Factory?

➤ Why HVAC System Is the Backbone of Modern Industrial Infrastructure

➤ How Does HVAC System Work in Commercial Buildings?

➤ Top HVAC Trends in 2025

Explore these blogs to learn more about choosing the right ducts, improving system efficiency, and staying updated with the latest HVAC trends.

Frequently Asked Question

For industrial environments, Stainless Steel ducts are preferred due to their corrosion resistance, strength, and low maintenance. Mild Steel can be used in dry, non-corrosive industrial areas where budget is a priority.

Yes. Stainless Steel ducts have a higher upfront cost due to material quality and fabrication requirements, but they offer long-term durability and lower maintenance costs. Mild Steel ducts are more budget-friendly but may require regular upkeep.

Mild Steel ducts are not ideal for humid or coastal areas unless they are properly galvanized or painted, as they are prone to rust. Stainless Steel is a safer choice for such environments.

Degree Day Pvt. Ltd., India’s largest manufacturer of Stainless Steel and Mild Steel ducts, provides fully customized solutions for any project, including different shapes, sizes, finishes, and fabrication types to fit residential, commercial, or industrial HVAC systems.

Degree Day is India’s largest manufacturer of Stainless Steel and Mild Steel ducts, offering high-quality, durable, and customized duct solutions. They combine expert design, precision fabrication, and rigorous quality checks to ensure optimal airflow, hygiene, and efficiency for all types of HVAC systems.