Lucknow has always been a city of balance, a blend of tradition and progress, of history and innovation. As the skyline continues to rise and new businesses establish themselves across the city, one thing has become clear: comfort and air quality are no longer luxuries, but essentials.

That’s where Degree Day steps in. With over 25 years of experience and ISO 9001:2015 certification, Degree Day has established itself as a trusted name in the world of HVAC design, manufacturing, and turnkey solutions across North India. Whether it’s a hospital requiring precision air control or a commercial complex demanding energy efficiency, the company has earned a reputation for delivering results that last.

More Than Just Air Conditioning: A Complete HVAC Experience

When people hear “HVAC,” they often think of cooling or heating systems. But true comfort goes beyond temperature. It’s about air quality, circulation, humidity, and even energy management.

Degree Day specializes in turnkey HVAC solutions, which means we handle every aspect of your project from the first consultation to the final commissioning. You don’t have to coordinate with multiple vendors or stress about technical details. Our experts take care of everything:

1. Site Evaluation: Understanding Your Space, Requirements, and Energy Needs.

2. System Design: Creating tailored solutions that perfectly fit your environment.

3. Installation: Flawless execution with safety and efficiency in mind.

4. Maintenance & Support: Routine inspections and reliable after-sales service to keep systems performing at their best.

It’s a smooth, worry-free experience, the way professional climate control should be.

Why Businesses Across Lucknow Trust Degree Day

Over the years, Degree Day has earned a reputation for precision, reliability, and genuine trust. Our journey has taken us across a wide range of industries, from advanced cleanrooms and large-scale manufacturing facilities to hospitals, retail spaces, and modern corporate offices.

In Lucknow and throughout Uttar Pradesh, we offer comprehensive HVAC solutions tailored to every type of space, including basement ventilation, cleanroom environments, hospitality setups, showrooms, residential complexes, commercial buildings, and full-scale industrial projects. Whatever the need, our focus remains the same: delivering comfort, efficiency, and performance that lasts.

Here’s what sets them apart:

1. Decades of Experience: With 25+ years in the HVAC industry, their team understands every technical and environmental challenge Lucknow presents.

2. Quality Without Compromise: All projects adhere to global standards, including ISHRAE and ASHRAE guidelines.

3. Energy Efficiency First: Their systems are designed to reduce energy costs while maintaining superior performance.

4. Customized Designs: Every project is unique, and so is every Degree Day solution.

5. Transparent Pricing: No hidden costs, no surprises, just honest, value-driven service.

From design to execution, Degree Day ensures that every system not only performs but also endures.

Trusted by India’s Leading Brands

Degree Day’s portfolio in Lucknow speaks volumes. Some of the region’s most respected names rely on our HVAC systems for efficient and reliable operations, a true mark of trust and capability.

Our Clients in Lucknow Include:

Kanpur Plastic, Viraj Constructions, Birla Dharamshala (Ayodhya), Lete Hue Hanuman Mandir, Safety Shoes Manufacturing Unit, Ex-CM Residence, Delhivery Warehouse (Lucknow), Ford Car Showroom, and many more.

Smart, Sustainable, and Ready for the Future

In today’s world, efficiency and sustainability go hand in hand. Degree Day integrates smart automation and eco-friendly HVAC technologies to help clients cut energy use without compromising comfort.

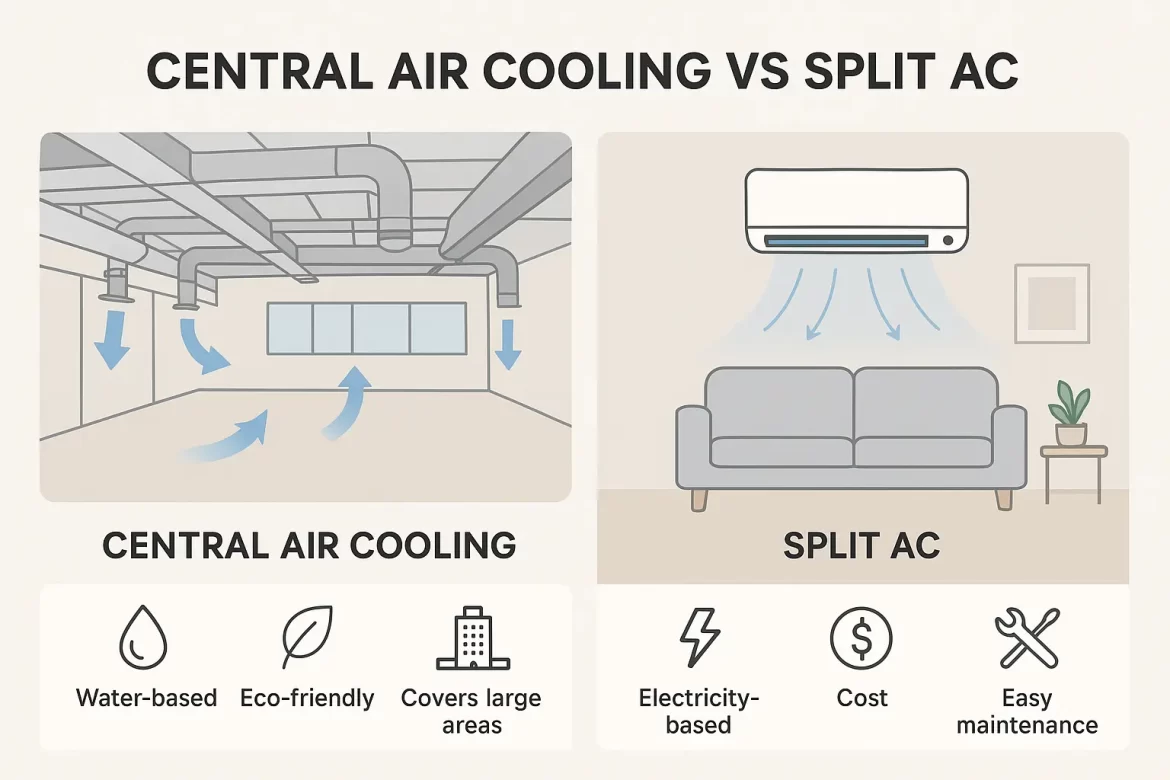

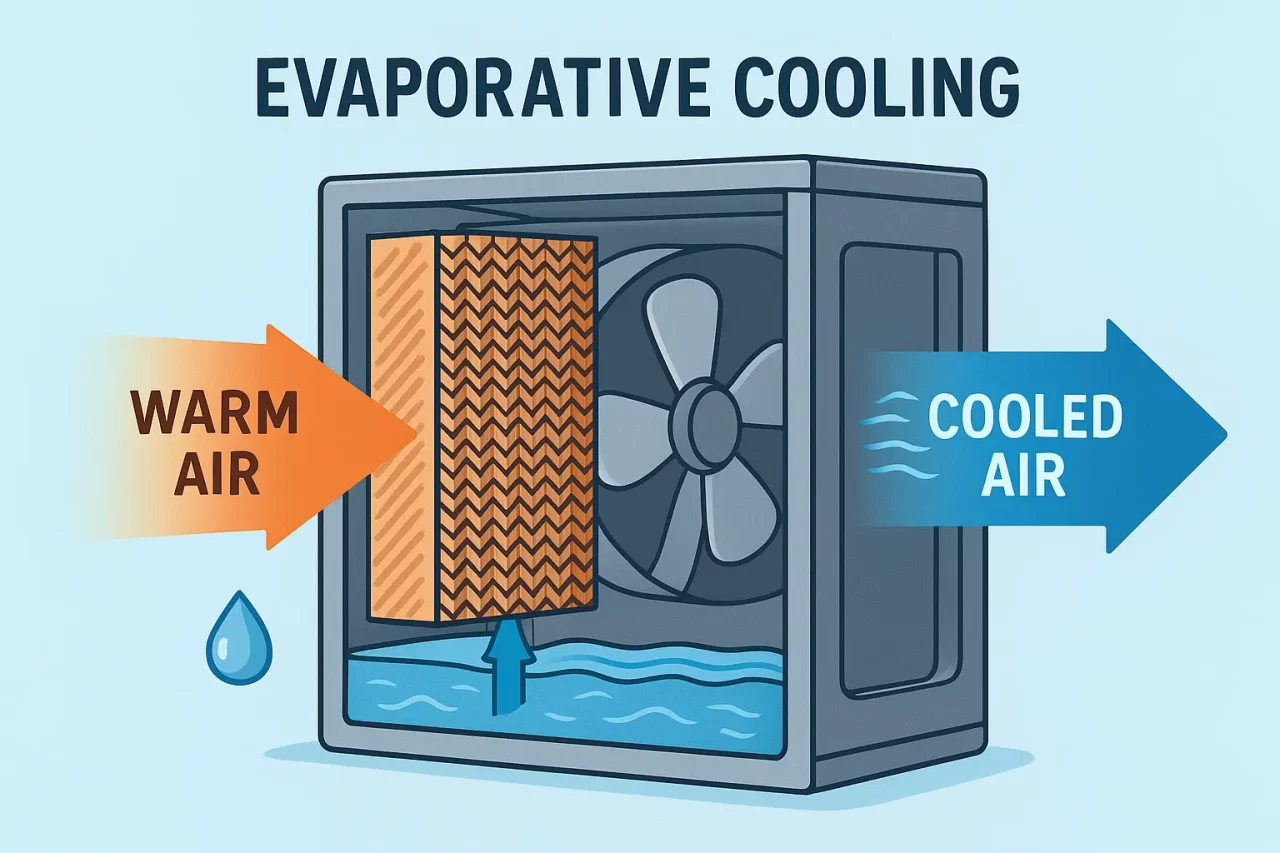

Our products & Services include centralized air conditioning, UVGI-based air purification, prefabricated ducts, Mist Cooling System, Bladeless Fans, Exhaust Fans, Basement Ventilation, HVAC Design, HVAC Projects, Clean Room Solution, HEPA Air Purifiers, Air Washer, Air Handling Units, Single, Dual and Hybrid Evaporative Cooling System, and smart energy control, all engineered to ensure clean, safe, and sustainable indoor environments.

Whether it’s a high-end commercial space or an industrial setup, Degree Day’s team ensures the perfect balance between technology, performance, and environmental responsibility.

Why Local Expertise Matters

Lucknow’s climate can be unpredictable sweltering summers, humid monsoons, and chilly winters. Generic systems simply don’t cut it here. Our deep understanding of local weather patterns and building needs means their solutions are built for real conditions, not assumptions.

We don’t just install machines; we design environments where people can work, heal, and live comfortably all year round.

Building Better Air, Together

Comfort isn’t just about cooling a room; it’s about creating spaces that help people feel better, work smarter, and breathe easier. That philosophy drives everything Degree Day does.

Whether you’re planning a new project or upgrading an existing system, Degree Day is ready to design, deliver, and maintain an HVAC solution that aligns with your vision and budget.

Quick Highlights

● 25+ years of HVAC expertise

● ISO 9001:2015 Certified

● Turnkey project design & execution

● Energy-efficient and eco-friendly systems

● Trusted by India’s leading brands

Frequently Asked Questions

With 25+ years of experience and ISO 9001:2015 certification, Degree Day delivers reliable, high-performance HVAC systems. From design to maintenance, every project is tailored for efficiency, durability, and Lucknow’s unique climate.

They offer complete HVAC solutions – centralized AC, air purification (UVGI + HEPA), prefabricated ducts, air washers, evaporative air coolers, air purifiers, cleanroom systems, ventilation setups, and hybrid cooling for homes, offices, and industries.

Yes. Degree Day manages turnkey projects from site evaluation and design to installation, commissioning, and maintenance—ensuring a smooth, worry-free process.

Lucknow’s hot, humid climate needs specialized systems. Degree Day’s local experience ensures efficient, weather-optimized solutions that perform year-round.

Trusted by brands like Kanpur Plastic, Viraj Constructions, Birla Dharamshala (Ayodhya), Lete Hue Hanuman Mandir, and Ford Showroom, among others.