In industrial HVAC systems, ducts serve as the lifelines that distribute conditioned air throughout spaces such as factories, warehouses, plants, and commercial complexes. Choosing the right duct type is not just about airflow; it impacts maintenance costs and overall project performance.

According to industry studies, improper duct selection and installation can increase energy costs by up to 30% in large facilities. That’s why industrial engineers and HVAC contractors place significant emphasis on duct type, size, and installation method when planning HVAC systems.

Why Duct Selection Matters in Industrial HVAC Projects

The correct duct type ensures:

- Energy Efficiency: Minimizing air leakage reduces power consumption.

- Airflow Performance: Maintains consistent airflow across long distances.

- Durability: Withstanding pressure variations and environmental conditions.

- Ease of Maintenance: Lower downtime and better long-term reliability.

- Compliance: Meeting SMACNA and international ducting standards.

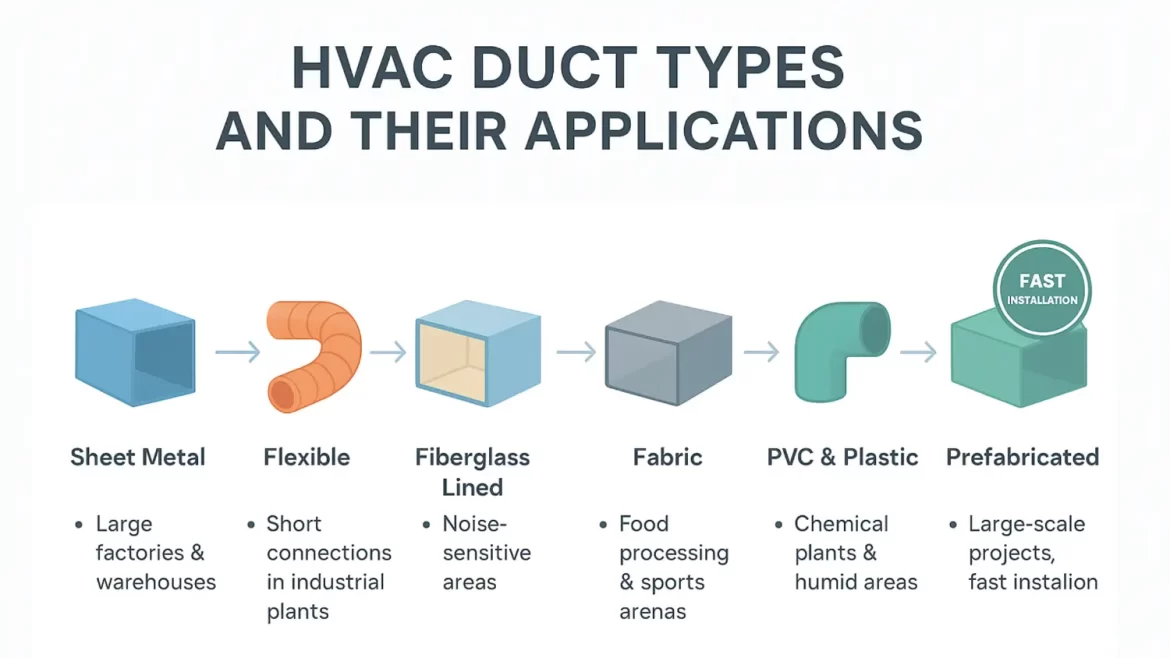

Types of HVAC Ducts in Industrial Applications

1. Sheet Metal Ducts

Material: Galvanized steel or aluminum.

Advantages:

- High durability and resistance to mold growth

- Smooth interior for better airflow

Applications: Factories, power plants, and large warehouses

2. Flexible Ducts

Material: Wire coil with a plastic or foil covering.

Advantages:

- Easy to install in tight spaces

- Cost-effective for short runs

Limitations & Applications: Not suitable for high-pressure systems. Connecting air outlets to main ducts in industrial facilities

3. Fiberglass Lined Ducts

Advantages:

- Built-in insulation reduces noise

- Improves thermal control

Applications: Industrial offices, laboratories, and noise-sensitive environments

4. Fabric Ducts (Textile Ducting)

Material: Permeable or non-permeable textile.

Advantages:

- Even air distribution

- Lightweight and corrosion-resistant

Applications: Food processing plants, sports arenas, large open halls

5. PVC & Plastic Ducts

Advantages:

- Excellent corrosion resistance

- Lightweight and moisture-resistant

Applications: Chemical plants, marine facilities, and humid environments

6. Prefabricated Ducts – The Modern Industrial Choice

Prefabricated ducts are manufactured in a controlled environment off-site and delivered ready for installation. This method ensures precision, faster project timelines, and reduced wastage.

Key Benefits:

- Consistent quality with strict dimensional accuracy

- Faster installation with minimal on-site fabrication

- Reduced labor costs and project delays

- Better sealing and reduced air leakage

7. Stainless Steel Ducts: Offers excellent corrosion resistance and can handle higher temperatures, making it suitable for Kitchen exhaust applications.

Greencon’s Prefabricated Ducting Solution

With over 25 years of expertise in HVAC ducting, Greencon offers a state-of-the-art prefabricated duct manufacturing setup that meets international standards.

Why Greencon Prefabricated Ducts Stand Out:

- Precision Engineering: Seamless integration into HVAC and ventilation systems.

- Efficiency: Engineered for maximum airflow and energy savings.

- Versatility: Ideal for industrial facilities, basement ventilation, and large-scale commercial projects.

- Technical Compliance: Designed in accordance with SMACNA – HVAC Duct Construction Standards (Metal & Flexible).

Technical Excellence – Flange Class & Duct Gauge Selection

Greencon selects flange class and duct gauge based on duct size and static pressure for optimal performance.

Example: 701–750 mm ducts:

- At 1″ w.g. static pressure → TDC Flange, 26 gauge

- At 4″ w.g. static pressure → TDC Flange, 24 gauge

(Your engineers handle these selections to ensure system efficiency and durability.)

Choosing the Right Duct Type for Your Industrial Project

When selecting a duct type, consider:

- Airflow Requirements – high-volume vs. low-volume systems

- Static Pressure Class – for pressure handling capacity

- Material Compatibility – for corrosion or moisture resistance

+ Installation Timeline – prefab ducts for faster projects

+ Budget Constraints – balancing cost with long-term performance

Common Installation Mistakes to Avoid in Duct Installation

– Using undersized ducts that restrict airflow

– Failing to seal joints properly, causing leakage

– Sharp bends that reduce air velocity and efficiency

Quick Comparison Table – HVAC Duct Types

The right duct choice can dramatically improve energy efficiency, airflow, and overall HVAC performance in industrial projects.

| Duct Type | Durability | Installation Speed | Best For | Limitations |

| Sheet Metal | High | Medium | Factories, warehouses | Heavier, more labor-intensive |

| Flexible | Low-Med | High | Short connections | Not for high-pressure systems |

| Fiber glass-lined | Medium | Medium | Noise-sensitive environments | Can trap dust if damaged |

| Fiber glass-lined | Medium | High | Food processing, sports arenas | Limited pressure handling |

| PVC & Plastic | Medium | Medium | Chemical plants, humid spaces | Not for very high temperatures |

| Prefabricated (Greencon) | High | Very High | Large industrial projects, fast-track installations | Requires transport logistics |

With 25 years of expertise, Greencon’s Prefabricated Ducting Solutions deliver unmatched speed, precision, and compliance with international standards — making them the preferred choice for modern industrial applications.